2014 Yarn Production Machinery

2014 Yarn Production Machinery

Vraag ons om de prijs

Plaats:Turkije

Beschikbaar aantal:10

Beschrijving

YARN PRODUCTION MACHINERY:

2X 2014 RIETER A11 UNIFLOC MACHINE

2X 2014 RIETER A48 HEAVY METAL SEPARATOR

2X 2014 RIETER B12 UNICLEAN

2X 2014 RIETER B76 UNIMIX

2X 2014 RIETER A79 UNISTOR

2X 2014 RIETER A21 CONDENSER

2X 2014 JOSSI MAGIC EYE

2X 2014 JOSSI TVS XSPECT

1X 2014 RIETER B25 WASTE OPENER

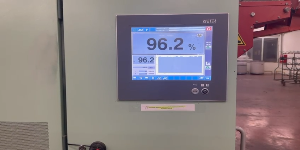

1X 2014 RIETER UNICONTROL

2X 2015 ARGEMA SMT 64500

14X 2014 RIETER C70 CARD MACHINE

4X 2016 RIETER C70 CARD MACHINE

6X 2014 RIETER SB-D 45

6X 2014 RIETER RSB-D 45

1X 2014 RIETER SPIDERWEB

10 X 2014 RIETER R60 Open End Spinning

• Make : Rieter

• Model : R60

• Year : 2014

• No of Rotors : 600

• Yarn Clearer Make : Rieter Q10

• Piecer Carriage : 4

• Opening Roller Type : B174 N-64

• Rotor Diameter in mm : 33

• Length Measuring : Available

• Type of Spinbox : R60

• Type of Drum : SRZ

• Conicity : Cylindrical

• Rotor Drive Type : Aero - bearing

• Rotor Type : 33–XT-BD-AE1

The R 60 offers up to 540 spinning positions per machine. This

makes it the longest rotor spinning machine in the world. With

this large number of rotor positions, high delivery speeds of up

to 260 m/min are possible. Shorter machines can even achieve

speeds of up to 350 m/min. Rotor speeds up to 170 000 rpm

complete the high productivity potential.

TECHNOLOGICAL ADV ANCE WITH THE S 60 SPINNING UNIT

The new S 60 is based on the outstanding properties of the SC-R

spinning box, supplemented by valuable innovations. All the main

advantages, such as BYpass, fixed fiber support, fixed fiber tuft

support and SPEEDpass are also to be found in the new S 60 unit.

With the R 60, rotor speeds up to 5 % higher can be achieved

without jeopardizing yarn quality. The new spinning geometry of

the R 60 lowers spinning tension. The result is fewer yarn breaks

during spinning and better working capacity of the yarn produced

for the next process.

The “cool nozzle” design prevents fiber accumulations and improves

heat dissipation in the technologically important area of

the exit nozzle. Especially when producing synthetic fibers, the

cooling effect of “cool nozzle” technology has a very positive impact

on productivity and quality.

USER-FRIENDLY AUTOMATIO N CONCEPT

The simple, modular design of the robots on the R 60 permits

fast cycles for package changing (doffing), piecing and rotor

cleaning in just 20 seconds.

The R 60 can be equipped with up to 4 of these fast robots

• providing the highest machine efficiencies

• producing strong and invisible piecings with AEROpiecing®

• cleaning the rotor grooves perfectly with VARIOclean at each

piecing and doffing cycle.

Only Rieter provides individual robot service stations at the

foot end and headstock of machines with more than 2 robots.

They enable the other robots to easily take over service for the

whole machine if one of the robots is undergoing maintenance.

The user-friendliness of Rieter automation systems for rotor

spinning machines is mill-proven and well established. Your

maintenance staff will enjoy working with the R 60 robots.

Settings are made very comprehensively by means of the

unique eXpert Piecing System XPS. Only 6 parameters have

to be set on the robot’s graphic display. Ergonomics and short

maintenance times are guaranteed.

PRODUCTIVITY

• Machine length of up to 540 positions with rotor speeds

up to 170 000 rpm

• Higher machine efficiency with lower spinning tension,

resulting in fewer yarn breaks

• Higher speeds with synthetic fibers thanks to “cool nozzle”

technology

• Very fast robots for high machine efficiency even at high rates

of ends down and clearer cuts

• Minimal operator cost, using large can and package sizes of

up to 6 kg and 350 mm diameter

FLEXIBILITY

• Independent machine sides to produce two different lots

simultaneously (option)

• Easy lot change with all spinning elements and the new

TWISTunit

• VARIOspin (option) powered by Amsler Tex for the production

of high-quality slub yarns with maximum productivity

• 1, 2, 3 or 4 robots with service stations for easy robot service

with little influence on machine efficiency

• Double capacity tube loader with independent sides (option)

QUALITY

• Superior yarn evenness and quality with the new S 60

spinning unit

• ”Cool nozzle“ technology prevents fiber damage, especially

with synthetic fibers

• Superior running performance achieved with adjustable

trash extraction using BYpass

• Highest yarn quality due to the fixed fiber tuft support

and SPEEDpass (optional)

• Broad spinning component portfolio for optimal yarn

construction

• The Rieter rotor yarn is branded under the name Com4®rotor

ECONOMY

• Up to 5 % less energy consumption thanks to newly designed

rotor geometry and suction system

• Low loss of good fibers thanks to the BYpass system of the

S 60 spinning unit

• Good space utilization due to narrow machine design

and 540 spinning positions

• Easy access for fast operation and maintenance

ADITIONAL MACHINES & EQUIPMENT

1X 2014 KAVURLAR AST BOX FIBER BALING PRESS (60 TON)

4X 2014 TEMSANAIR CONDITIONING UNIT (9000 ROTOR)

2X 2014 EKOMAK EKO132 QD VST 32KW SCREW AIR COMPRESSOR (WITH INVERTER)

1X 2014 EKOMAK CAD 500 COMPRESSED AIR DRYER

2X 2014 EKOMAK G 430 COMPRESSED AIR FILTER

1X 2014 EKOMAK 5000LT COMPRESSED AIR TANK

1X 2014 PREMIER ART2-LSMCT FULLY AUTOMATIC HIGH VOLUME COTTON TESTING EQUIPMENT

1X 2014 PREMIER AQUARA2 PROCESS AND FIBRE INFORMATION SYSTEMS

1X 201 PREMIER TENSOMAX SINGLE YARN TESTER

1X 2013 PREMIER İQ2 LX EVENNESS TESTER

1X 2014 STULZ CCU121A PRECISION CONTROLLED AIR CONDITIONING DEVICE (FOR

LABORATORY)

1X 2014 ZANCANER PACKAGING MACHINE

1X 2014 XQRELLA XSC-R 2900*1400* YARN FIXING MACHINE

1X 2007KIRAZ PALLET STRETCH PACKAGING MACHINE

8000X BIANCO BI.470*1070YK SPINNING CANS WITH SPRING SYSTEMS

280X BIANCO BI.1000*1200YKT SPINNING CANS WITH SPRING SYSTEMS AND CASTORS

1X 2015 BRACKER GRINDING MACHINE

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specificaties

| Fabrikant | Yarn Production Machinery |

| Jaar | 2014 |

| Conditie | Gebruikt |

| Voorraad nummer | 1337 |