1999 Schoen+Sandt TYP 7320

1999 Schoen+Sandt TYP 7320

Vraag ons om de prijs

Plaats:Zagreb, Kroatië

Beschikbaar aantal:3

Beschrijving

1985 Schoen+Sandt TYP 7320

1986 Schoen+Sandt TYP 7320

1999 Schoen+Sandt TYP 7320

A few years ago new Siemens controls were installed.

Machines regularly maintained according to manufacturer specifications either by the manufacturer or by our in-house technicians!

The machines have been dismantled and stored, but are in very good condition.

1.0 General description

se oen + san t

schoen + sandt mach i nery GmbH

Roller punching machine with preparation tables, for

for punching leather hides with the following

main features:

- Very stable steel construction of the machine with a

roller diameter of 400 mm, with high static and dynamic

dynamic load capacity. This results in a longer service life for

tools and punching underlays and thus leads to a reduction in

reduction in operating costs.

- Mounting of the shaft journal of the punching rollers by means of

clamping elements. With continuous shaft without

break-proof welded connection.

- Guides of the height adjustment made of maintenance-free and

maintenance-free and wear-resistant LUYTEX ®.

- Separate synchronised drives for the punching rollers. No mechanical

mechanical wear parts.

- Automatic plate transport

Friction wheel drives.

by means of low-maintenance

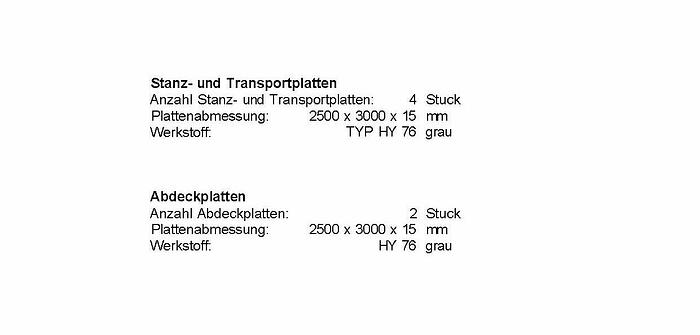

- Functional principle with sandwich plate (cover plate) for

increase tool life and protect the punching rollers.

punching rollers.

- Optimised process sequence to avoid double cuts.

- Smooth start-up and braking process thanks to frequency-controlled drives.

drives. This reduces wear on the drive elements.

The displacement of the applied punching knives is

largely excluded.

- Ergonomic working height of approx. 800 mm.

- Preparation tables accessible from every side in conjunction with

with safe automatic top feed devices.

- Throughfeed adjustment via servomotor with positioning control,

This means that each preparation table can be

separate knife height adjustment is possible for each preparation table.

- Automatic cleaning

Compressed air pulses.

of the light sensor optics by

- Modern Siemens S7 control system for trouble-free operation, with

long availability of spare parts and intuitive, menu-driven operation

operation via touch panel.

- Telephone modem for remote diagnostics, to minimise downtimes and

downtime and service costs in the workshop.

- Plain text error display, errors are displayed in plain text and not as an error code.

error code.

- Peripheral communication via passive distributor system with integrated

integrated function monitoring via LEDs, resulting in

unified electrical assembly, higher operational reliability and

and quicker troubleshooting in the event of a fault.

- Monitoring of the sandwich height via point light barrier.

- Use of high-quality components from reputable manufacturers

(see Schoen + Sandt standard parts list).

- Delivery with comprehensive documentation inki.

Circuit diagrams and in conformity with the applicable EN and CE regulations.

- Stable design maintenance of the type series to "current

state of the art" based on decades of experience with

comparable machines in the various stages of technical

technical progress.

- Energy optimisation, drives are only switched on when

switched on only when required.

- References all over the world (reference list on request).

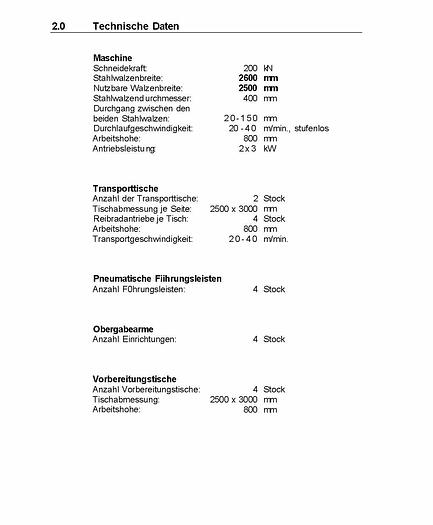

General technical data

Colour scheme

Machine: Safety guard, Post: Safety guard, Grille: Switching ran k:

RAL 7035 light grey

RAL 1004 yellow

RAL 9005 black

RAL 7035 light grey

Operating voltage: 400 V/ 50 Hz Pneumatics Operating pressure: 6 - 1O bar Connection to

customer's air supply network.

se oen + san t

schoen +sandt mach inery GmbH

The machine complies with the applicable CE and EN regulations.

The scope of delivery includes documentation, spare parts list and wiring diagram

in accordance with the applicable EC machinery directives.

Tools, concrete and foundation work are not included in the scope of supply.

Power supply lines (electricity, compressed air, telephone connection ... ) must be prepared by the customer up to the system.

prepared by the customer.

The sound pressure level of the machine corresponds to the currently valid machine guidelines.

Depending on the tools used, punching underlays, punching material, floor conditions and environment,

and the environment, the values may vary and increased punching noise may occur.

n + sandt can be influenced.

Functional description:

Operation of the system in standard configuration

se oen + san t

schoen + sandt mach i nery GmbH

After a punching plate on the preparation table has been

material and punching knives have been placed on the preparation table, the

the <start release> indicator light lights up on the

control panel of the table by pressing the button

<Start run> button to start the automatic run

can be started.

The table stop on the transport table is automatically

lowered automatically, the top delivery arms swivel out and the

the punching plate is manually pushed onto the transport table

until the transport wheels take over the further transport.

transport. The automatic work sequence begins as follows

as follows:

The "sandwich" plate is located in the lifting station of the transport

transport table onto which the punching plate has been pushed.

was pushed onto.

When the punching plate is fully positioned on the transport table

table, the lifting device lowers and places the "sandwich" plate

plate onto the knives. The transport wheels are swivelled

swivelled and transport the punching plate between the

between the punching rollers through the machine.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specificaties

| Fabrikant | Schoen+Sandt |

| Model | TYP 7320 |

| Jaar | 1999 |

| Conditie | Gebruikt |

| Voorraad nummer | 1232 |