2020 URTASUN TECNOLOGÍA ALIMENTARIA

2020 URTASUN TECNOLOGÍA ALIMENTARIA

Vraag ons om de prijs

Plaats:Łódź, Polen

Beschrijving

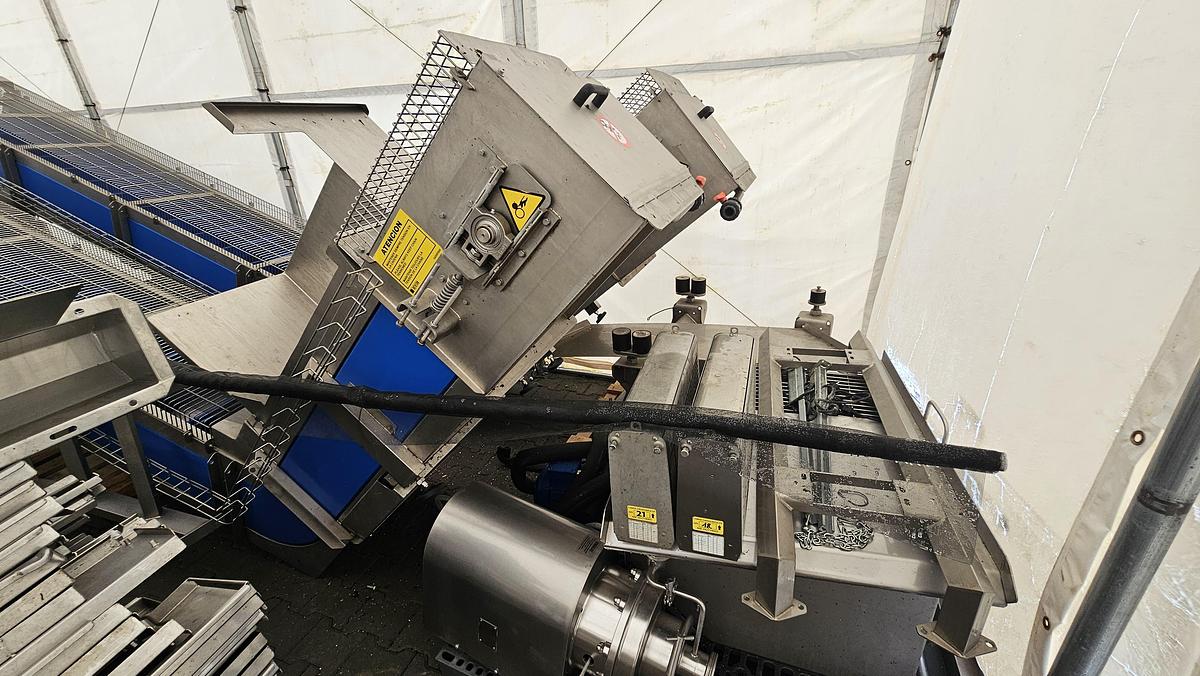

Food conveying and processing equipment / CURRENTLY DISMANTLED

LIST OF EQUIPMENT:

1.Incline auger conveyor (fabricated in Q4 2020)

2.Fruit declumper/breaker (fabricated in Q4 2020)

3.Metal detector shaker (metal detector head not included) (fabricated in Q4 2020)

4.Redler elevator (fabricated in Q4 2020)

5.Grading shaker with an additional set of screens (fabricated in Q4 2020)

6.Horizontal belt conveyor (fabricated in Q4 2020)

7.Redler elevator (fabricated in Q4 2020)

1. INCLINE AUGER CONVEYOR

Dimensions:

Length: 2.300 mm

Width: 1.500 mm

Features:

Fully built in stainless steel.

Accumulation hopper of 1 m3 capacity made of textured stainless steel.

Cleaning window at the lower part of the hopper.

Evacuation screw of 300 mm diameter built in stainless steel.

Open upper side of the screw for cleaning.

Draining valve for cleaning.

Upper screens to avoid big frozen blocs.

Safety protections.

2. FRUIT DECLUMPER/BREAKER

Dimensions:

Length: 1.600 mm.

Width: 600 mm.

Features:

Fully built in Stainless Steel AISI-304.

Grinder drums composed by:

Solid core.

Solid fingers for grinding.

Stainless steel sprockets.

Supporting box for production by means of the grinders or without grinders.

Stainless steel bearings.

Safety protections.

Powered by means of SEW motoreducer.

3. METAL DETECTOR SHAKER (metal detector head not included)

Dimensions:

Length: 4.000 mm

Width: 700 mm.

Features:

Fully built in stainless steel.

Tray fully built-in stainless-steel plate, composed by:

First level with screens for the single product

Not single product remover area, included in the first level.

Second level with screens to remove the small pieces and juice.

Juice collecting level and drainage outside the machine.

Second level exit, for the good product made in PE blue to pass trough the metal detector.

Vibration by means of fibber springs working at high frequency.

Reaction mass in 5 mm stainless steel plate.

Isolation by means of rubber silent blocks.

Chassis in stainless steel structural profile for the required working height.

Powered by-mass motor-vibrators (OLI trademark).

Supported over columns.

4. REDLER ELEVATOR

Dimensions:

Upper horizontal track: 1.800 mm.

Lower horizontal track: 1.900 mm.

Height of charge: 600 mm.

Height of discharge: 3.850 mm.

Width of blades: 500 mm.

Inclination: 60 º.

Features:

Built of stainless steel AISI 304. Thickness of the bottom plate 4mm (electro-polished)

Stainless steel dragging conveyor belt on deslidur guide with Z-18 sprocket. URTASUN certified chain.

Blue polythene pusher blades.

Driven by SEW motor gearbox.

Auto tension system.

Anti-return system.

Stainless steel bearings with Stainless steel housing.

Protection safety; stainless steel round bars.

Manual cleaning gate (easy sliding) placed in the lower horizontal track.

Diagonal exit.

5. GRADING SHAKER WITH SET OF SCREENS

Dimensions:

Length: 4.800 mm

Width: 800 mm.

Sizes: 3 sizes + 1 over sizes = 4 sizes.

Features:

Fully built in stainless steel.

Tray fully built-in stainless-steel plate, composed by:

6 grading screens of 600x800mm with easy adjustment. 50 mm step between each set of 2 size’s screens. Note additional set of 27 screens is included in the offer.

Size collecting hopper for every 2 screens, to collect in total 3 sizes.

Connecting chute between hopper and downstream equipment

Exit of oversize by the front of the shaker.

Connecting chute from front exit to a container for oversize.

Vibration by means of fiber springs working at high frequency.

Reaction mass in 5 mm stainless steel plate.

Isolation by means of rubber silent blocks.

Chassis in stainless steel structural profile for the required working height.

Powered by-mass motor-vibrators (OLI trademark).

Supported over columns.

Power supply: 2 Kw.

6. HORIZONTAL BELT CONVEYOR

Dimensions:

Length: 5.200mm.

Width: 600mm.

Features:

Fully built in Stainless Steel AISI-304.

Belt Intralox thermoplastic and modular material.

Traction by thermoplastic sprockets.

Retaining sides.

Floating scraper for cleaning of the belt.

Driven by pendular SEW motor gearbox.

Back lock and motor gearbox cover.

Side protections placed in transmission zones to avoid risk of entrapment.

Stainless Steel bearings.

7. REDLER ELEVATOR

Dimensions:

Upper horizontal track: 1.300 mm.

Lower horizontal track: 1.700 mm.

Height of charge: 600 mm.

Height of discharge: 2.600 mm.

Width of blades: 500 mm.

Inclination: 60 º.

Features:

Built of stainless steel AISI 304. Thickness of the bottom plate 4mm (electro-polished)

Stainless steel dragging conveyor belt on deslidur guide with Z-18 sprocket. URTASUN certified chain.

Blue polythene pusher blades.

Driven by SEW motor gearbox.

Auto tension system.

Anti-return system.

Stainless steel bearings with Stainless steel housing.

Protection safety; stainless steel round bars.

Manual cleaning gate (easy sliding) placed in the lower horizontal track.

NOTE: THE DEWATERING SHARKER IS NOT INCLUDED.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specificaties

| Fabrikant | URTASUN TECNOLOGÍA ALIMENTARIA |

| Jaar | 2020 |

| Conditie | Gebruikt |

| Voorraad nummer | 749 |