2004 Mazak Integrex 100-III

2004 Mazak Integrex 100-III

Plaats:Erfurt, Duitsland

Beschrijving

06.01.2005 Commissioning in our tool shop. Since then programmed and operated by the same worker. (Single shift, with a high proportion of programming time).

12.05.2005 Pocket at the tool changer changed and measured

16.01.2009 Model update SK1069 ATC parameters

03.05.2012 Controller MDS-CH-V2-3520 exchanged

12.06.2013 Tooleye exchanged

12.06.2019 Tooleye exchanged

08.12.2021 Mill spindle exchanged

16.12.2022 Brake X-axis exchanged

About 20 Capto tool holders can be sold together with the machine.

The Mazak Integrex 100-III is a CNC (Computer Numerical Control) multi-tasking lathe and milling machine manufactured by Yamazaki Mazak Corporation, a Japanese machine tool builder known for producing high-quality machining equipment. The Integrex series is renowned for its ability to perform a wide range of machining operations, including turning, milling, drilling, and more, all in a single setup.

Key Specifications and Features of the 2004 Mazak Integrex 100-III:

Machine Type: CNC Multi-Tasking Lathe/Milling Machine.

Chuck Size: The Integrex 100-III typically features a chuck size of 6 inches or 8 inches, which refers to the maximum diameter of workpieces it can hold.

Maximum Swing Diameter: This specification refers to the largest diameter of the workpiece that can be accommodated by the machine when rotating.

Maximum Machining Length: The maximum length of the workpiece that can be machined on this machine. This is determined by the distance between the chuck and the tailstock.

Spindle Speed: The spindle speed indicates how fast the machine's spindle (rotating component) can rotate. It is usually expressed in RPM (Revolutions Per Minute).

Spindle Motor Power: This specification represents the power of the spindle motor, often measured in horsepower (HP) or kilowatts (kW). It determines the cutting capability of the machine.

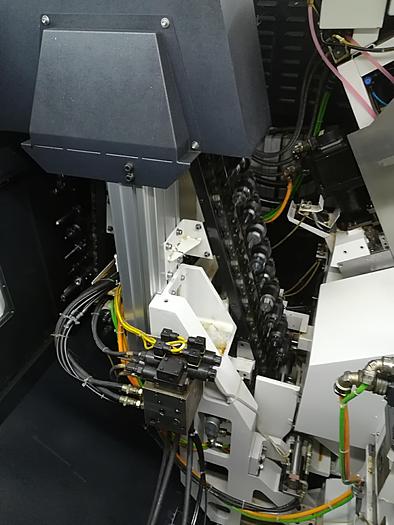

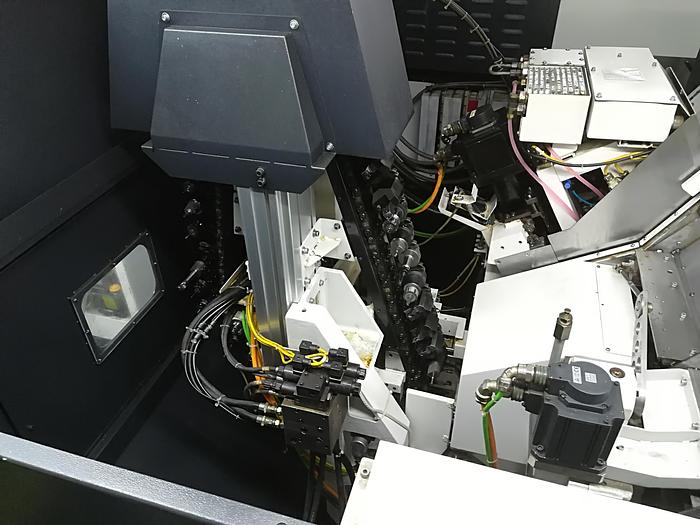

Number of Tool Stations: The Integrex 100-III is equipped with a tool turret that holds multiple cutting tools. The number of tool stations can vary, and it allows for automatic tool changes during machining operations.

Control System: Mazak machines typically use the Mazatrol control system or a Fanuc CNC control system. These systems provide the operator with precise control over the machine's movements and functions.

Axis Configuration: The Integrex 100-III is known for its multi-axis capabilities, which can include X, Y, Z, and C-axis for complex machining operations.

Coolant System: A coolant system is essential for maintaining the temperature of the cutting tools and workpiece during machining, preventing overheating and ensuring accuracy.

Tool Presetter: This feature allows for precise tool measurement and setup, optimizing tool changes and reducing downtime.

Automatic Tool Changer: The machine typically includes an automatic tool changer to facilitate efficient tool changes during machining.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specificaties

| Fabrikant | Mazak |

| Model | Integrex 100-III |

| Jaar | 2004 |

| Conditie | Gebruikt |