2012 Haas ST 20

2012 Haas ST 20

Location:Vienna, Austria

Description

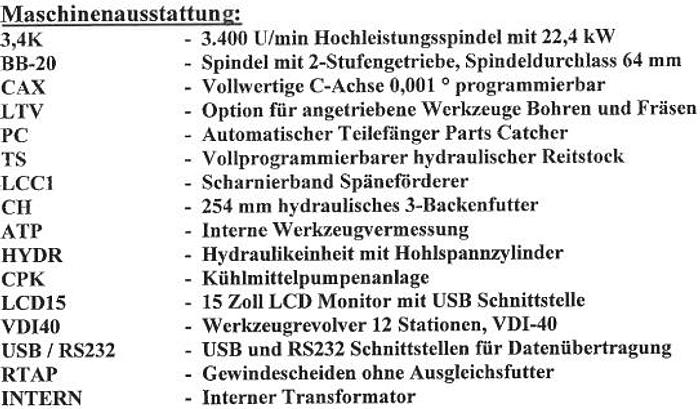

HAAS ST 20 CAX "Big Bore"

Tool holder form B2 radial, left

VDI 40

Number of pieces 12

NC holder E2-40x(Ø10-40) , boring bar holder

VDI 40

Number of pieces 20

(axial) Straight drilling/separating unit -for ER collets

VDI 40

Number of pieces 3

ER collet chuck

VDI 40

Number of pieces 5

(radial) angled drilling/separating unit -for ER collets

VDI 40

Number of pieces 4

Tool holder form C2 axial, left

VDI 40

Number of pieces 4

About the machine:

A new operating system (software) was installed this spring - unfortunately, the data was lost - but one can assume 2,000 h p.a..

Defects:

X Axle guides should be replaced, geometry adjusted and we would now also replace the chuck.

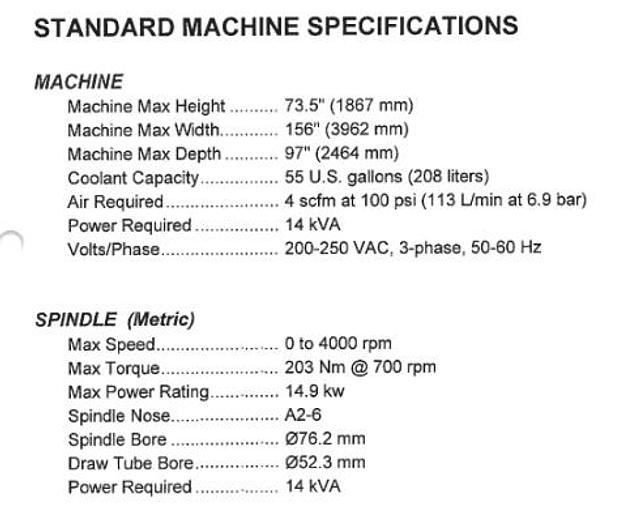

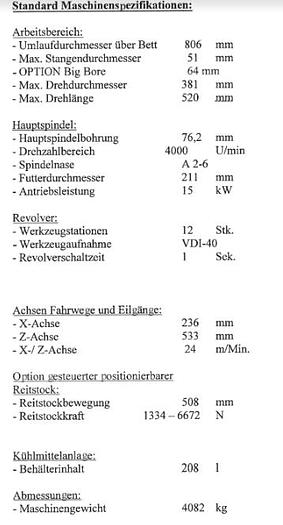

The ST-20 is part of the ST series of lathes and is designed for precision turning and machining operations. Below are some key details about the 2012 Haas ST-20 lathe:

- Year of Manufacture: 2012

- This indicates that the machine was manufactured in the year 2012. It's essential to know the manufacturing year for maintenance, compatibility, and potential upgrades.

- Machine Type: CNC Lathe

- The Haas ST-20 is a computer-controlled lathe designed for turning operations. It's used to cut, shape, and machine various materials, including metal, plastic, and more.

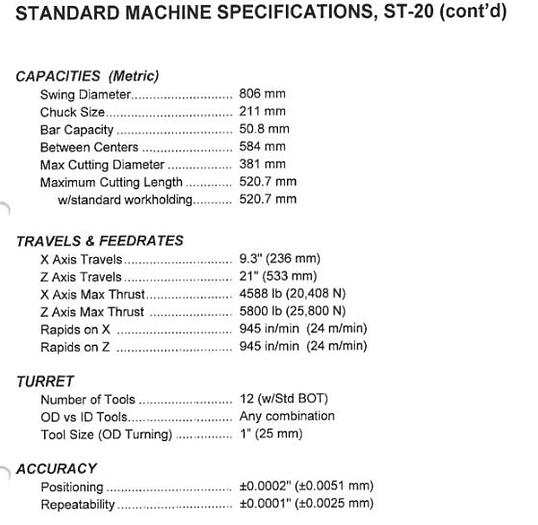

- Max Turning Diameter: Approximately 10.3 inches (260 mm)

- The ST-20 has a maximum turning diameter, which means it can turn workpieces with a diameter of up to approximately 10.3 inches (260 mm).

- Max Turning Length: Approximately 21 inches (533 mm)

- The maximum turning length indicates the length of the workpiece that can be accommodated in the machine for turning operations. In this case, it's about 21 inches (533 mm).

- Spindle Speed: Varies

- The spindle speed of the ST-20 can be adjusted and programmed to suit the specific machining requirements. Haas lathes typically have a wide range of spindle speeds.

- Spindle Nose: A2-6

- The spindle nose designation specifies the type of spindle nose used on the machine. In this case, it's an A2-6, which is a common type in CNC lathes.

- Tool Turret: 12-Station VDI Turret

- The ST-20 is equipped with a 12-station VDI (Verein Deutscher Ingenieure) turret. This turret holds tooling for various cutting and machining operations, allowing for tool changes during machining.

- Control System: Haas CNC Control

- Haas lathes are known for their user-friendly CNC control systems. The control system allows operators to program and control the machine's movements and operations.

- Axis Configuration: 2-Axis (X and Z)

- The ST-20 is typically configured as a 2-axis lathe, meaning it can move along the X and Z axes to perform turning and facing operations.

- Coolant System: Included

- The machine is equipped with a coolant system to keep the cutting tools and workpiece cool during machining, which is essential for achieving high-quality results.

- Tailstock: Included

- The tailstock is a component that provides additional support to the workpiece during machining. It can be used for drilling or other operations.

Find more here - https://www.ucymachines.com/

Contact us at - sales@ucymachines.com

Specifications

| Manufacturer | Haas |

| Model | ST 20 |

| Year | 2012 |

| Condition | Used |